Aluminum Extrusions

Standard Shapes

We offer a wide array of industry standard shapes for your convenience. We have solid flat bars and rounds. we also have round, square and rectangular tubing, channels, beams and angles. Many of our standard shapes can be found with both architectural and structural types.Die Catalog

Custom Shapes

Customers come to us with ideas. We take those ideas and turn them into solid form. Let us help bring your products to life via custom designs and dies manufactured to specification. Our line of custom extrusions will help you get started on your next project.Contact Us

Call or email us today with any questions. One of our experts is ready to help. Potential customers may also stop in and vistit our facility.(800) 338-5532

sales@bristolaluminum.com

5514 Bristol Emilie Road

Levittown, PA 19057

What sets us apart?

We pride ourselves on the relationships we foster with our customers. Rest easy knowing your business is in good hands. Our large library of dies, state-of-the-art equipment, knowledge, experience and extensive inventory make Bristol Aluminum the premiere aluminum extrusion company for many businesses. Our ability to offer quality products and excellent service have anchored Bristol Aluminum to the industry for over 65 years.Testimonials

"Bristol Aluminum has changed our opinions about what we look for in a vendor. Through seamless design and integration, we couldn't be happier about our choice for such an exemplary vendor. There's no comparison."- Michael Farinha

"Having been one of our quality suppliers for quite some time, we appreciate the clarity and flexibility that Bristol Aluminum offers. Our experience with them is always a pleasant one. They are definitely distinguished in their industry."

- Ashley Pinero

Additional Services

-

Cutting

Cutting to standard stock lengths is a service included with all orders. We also offer convenient and accurate precision and miter cutting for customers with specific tolerance needs. -

Material Finishing

Some customers require a wide array of secondary metal processes prior to product release. We offer a wide range of finishing options such as anodizing and powder coating to meet some of those needs. -

Tumbling

With our barrel tumbler, we are able to polish or improve the surfaces of small parts. Media and compounds are placed into a barrel tumbler and are circulated at a predetermined speed. By tumbling these pieces together with mixed medias and compounds, the friction between them gives us many positive results such as the rounding of corners, deburring, grinding, descaling, deflashing, burnishing, polishing and improving radial points and surface finish of small parts in bulk. -

Deburring

Burrs are a consideration for everyone in manufacturing. They are always present and can lead to problem for certain customers. We can remove the burrs from extruded parts by means of abrasive wheels and even hand-held tools following the precision cutting process. -

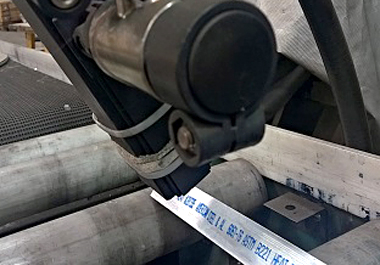

Stenciling

Our continuous ink jet printing capabilities are great for stenciling date coding and other traceability information onto our extruded materials based upon the requirements of our customers. -

Drilling

Our drill press has the power and precision necessary to meet your specific needs.